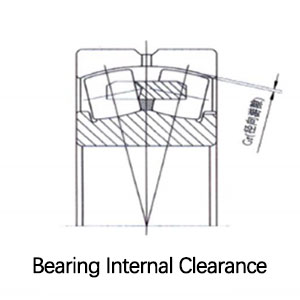

Definition of Bearing Internal Clearance

Bearing internal clearance is defined as the total distance through which one bearing ring can be moved relative to the other in the radial direction (radial internal clearance) or in the axial direction (axial internal clearance).

Initial Clearance vs Working Clearance

It is necessary to distinguish between the initial clearance and working clearance of a bearing before mounting. The initial internal clearance (before mounting) is greater than the operational clearance because:

- Different degrees of interference in the fits

- Differences in thermal expansion of bearing rings and associated components

These factors cause the rings to be expanded or compressed during operation.

Importance of Radial Internal Clearance

The radial internal clearance is critical for satisfactory operation:

- Ball bearings: Should maintain near-zero operational clearance or slight preload

- Cylindrical/spherical roller bearings: Should always retain residual clearance (however small)

- Tapered roller bearings: Typically require residual clearance except in stiffness-critical applications (e.g., pinion bearing arrangements) where preload is needed

Normal Clearance Group

The “Normal” internal clearance group is specially selected to provide suitable operational clearance when:

- Bearings are mounted with recommended fits

- Operating conditions are standard

Special Operating Conditions

When conditions differ from normal, such as:

- Interference fits on both bearing rings

- Significant temperature differentials

Bearings with greater or smaller internal clearance than Normal group may be required. WJY recommends verifying residual clearance after mounting in such cases.