Overview

Single-Row Four-Point Contact Ball Slewing Bearings are compact, high-performance rotational components designed to handle combined loads with exceptional efficiency.

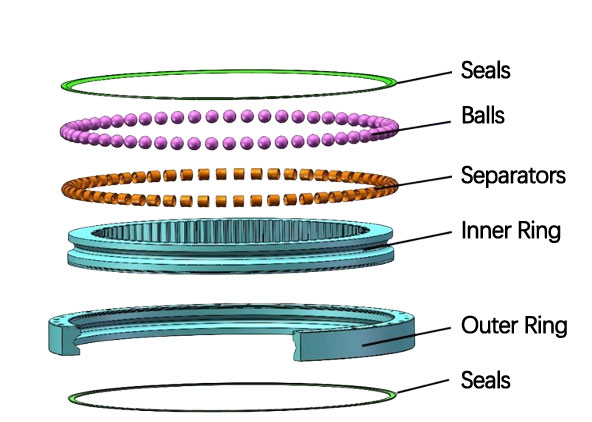

These bearings feature a unique design where each ball makes four contact points with the raceways, enabling them to simultaneously accommodate axial, radial, and moment loads from multiple directions. View Our Factory ProductsStructural Composition

- Outer Ring – The stationary component with precision-machined raceways

- Inner Ring – The rotating element with matching raceways

- Balls – High-grade steel balls that transmit forces between rings

- Separators – Maintain precise ball spacing and prevent contact

- Sealing System – Protects against contaminants and retains lubrication

- Mounting Holes – For secure installation to machinery

Four-Point Contact Principle

The defining characteristic of these bearings is the special “gothic arch” raceway geometry that creates four distinct contact points between each ball and the raceways:

- Two contact points with the outer ring raceway

- Two contact points with the inner ring raceway

Load Capacity

Single-row four-point contact ball slewing bearings are engineered to handle three types of loads simultaneously:

- Axial Loads – Forces parallel to the rotation axis

- Radial Loads – Forces perpendicular to the rotation axis

- Moment Loads (Overturning Moments) – Tilting forces that create rotational torque

Performance Advantages

- Compact cross-section

- Low rotational torque

- High rotational accuracy

- Cost-effective solution

- Easy installation

Gear Configuration Options

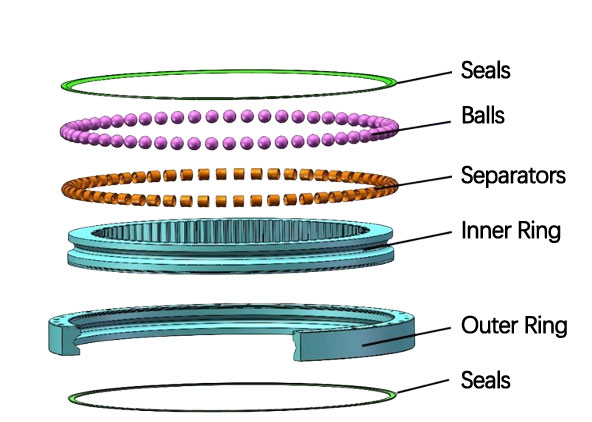

Non-Geared Type

- Simplest configuration

- Direct drive applications

- Minimal maintenance requirements

- Most cost-effective solution

- Compact design with minimal protrusions

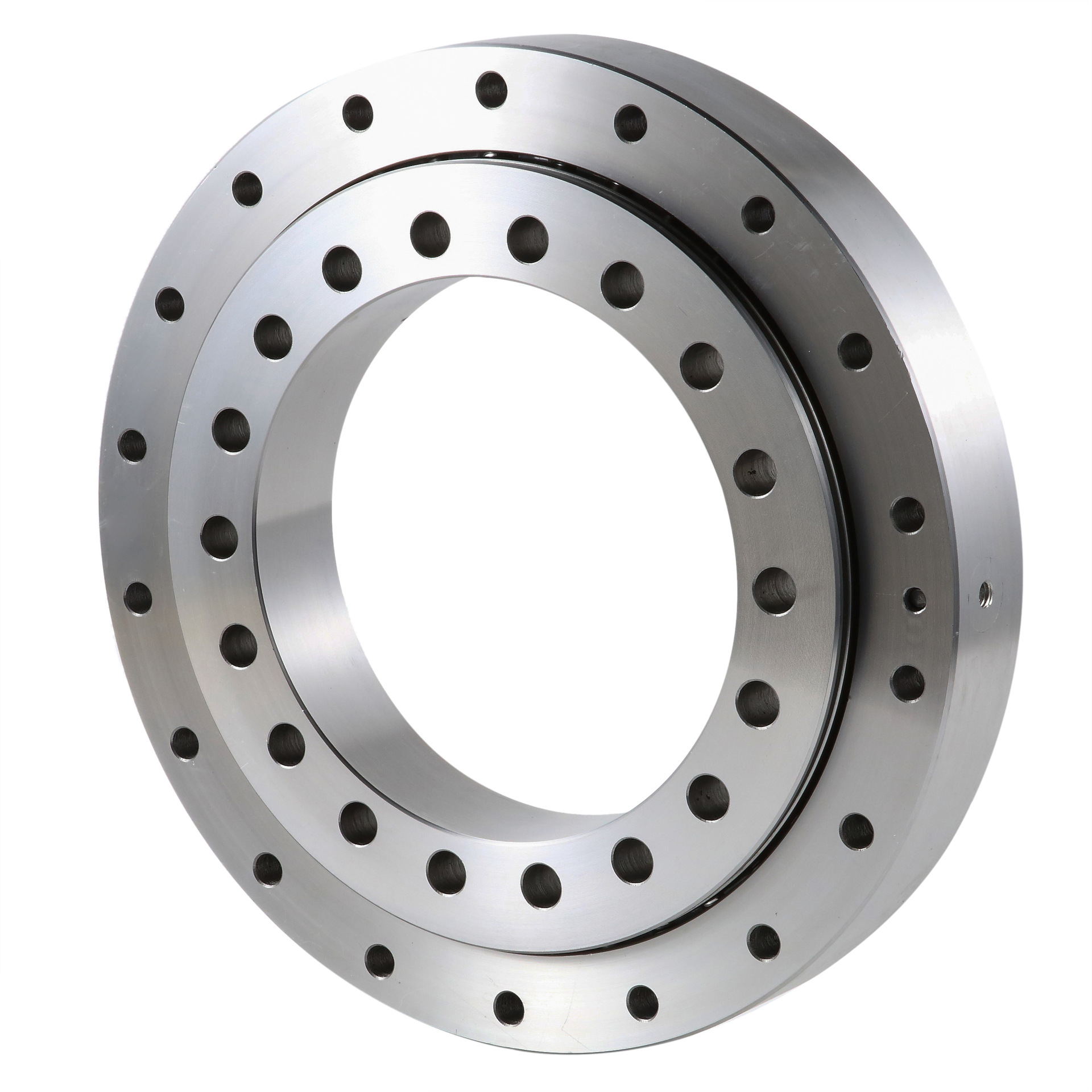

Internal Gear Type

- Gear teeth cut on inner ring bore

- Protected gear location

- Reduced contamination risk

- Compact external dimensions

- Preferred for space-constrained applications

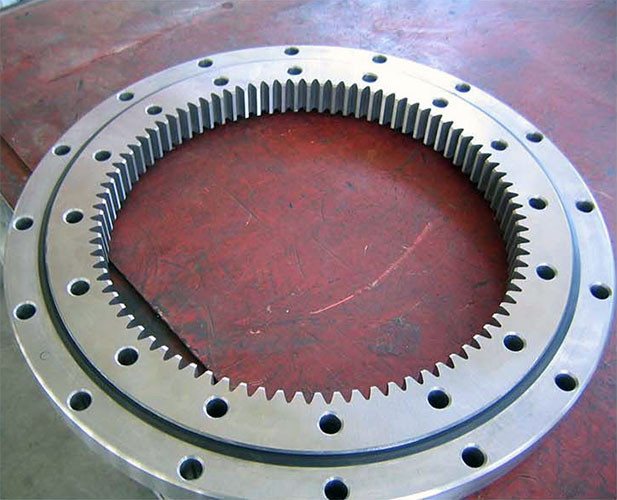

External Gear Type

- Gear teeth cut on outer ring circumference

- Easier maintenance access

- Higher torque transmission capacity

- Simpler lubrication access

- Wider pinion gear selection

Typical Applications

Construction Machinery

- Small to medium-sized excavators

- Mobile cranes (up to 50-ton capacity)

- Concrete pump trucks

- Aerial work platforms

- Compact loaders

Industrial Equipment

- Material handling turntables

- Packaging machinery rotators

- Welding positioners

- Indexing tables

- Light-duty wind turbine yaw systems

Selection Considerations

| Factor | Consideration | Recommendation |

|---|---|---|

| Load Capacity | Axial, radial and moment loads | Calculate all load components including dynamic factors |

| Gear Type | Non-geared, internal or external gear | Determine based on drive system requirements and space constraints |

| Mounting | Surface flatness and stiffness | Ensure mounting surfaces meet ISO standard tolerances |

| Operating Environment | Temperature, contaminants, corrosion | Select appropriate seals and lubrication |

| Rotational Speed | RPM requirements | Consider centrifugal forces at high speeds |

Maintenance Recommendations

- Regular lubrication intervals based on operating conditions

- Periodic inspection of seals for damage or wear

- Check for abnormal noise or vibration during operation

- Monitor gear teeth for proper meshing and wear patterns

- Keep mounting surfaces clean and properly torqued

Technical Specifications

Standard Sizing

- Bore diameters: 100mm to 2000mm

- Axial load capacity: 5kN to 1500kN

- Radial load capacity: 3kN to 800kN

- Moment capacity: 10kN·m to 1500kN·m

Material Specifications

- Rings: 42CrMo/50Mn alloy steel

- Balls: GCr15 bearing steel (HRC 60-65)

- Separators: Nylon 6/6 or brass

- Seals: NBR rubber with steel reinforcement