1. Detailed Structural Components

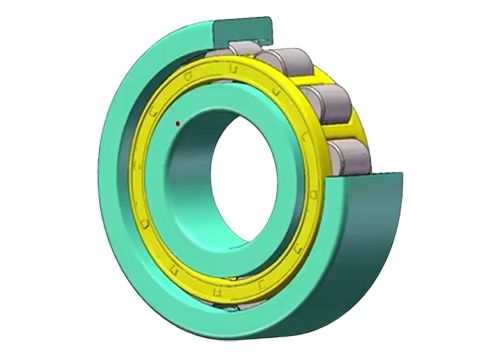

Cylindrical roller bearings consist of four fundamental components that work in precise coordination:

Outer Ring

- Manufactured from high-grade chromium steel (typically GCr15 or SAE 52100)

- Features hardened raceways with 58-64 HRC hardness

- May include ribbed designs for axial displacement control

Inner Ring

- Precision-ground to micron-level tolerances

- Often incorporates guide flanges for roller retention

- Heat-treated for optimal wear resistance

Roller Elements

- Cylindrical rollers with diameter/length ratios between 1:1 to 1:3

- Available in standard and full-complement configurations

- Surface finish of 0.05μm Ra for smooth operation

Cage Assemblies

- Common materials: pressed steel, brass, or polyamide

- Machined brass cages for high-speed applications

- Window-type designs for optimal lubrication flow

2. Performance Characteristics

Load Capacity Advantages

- 20-30% higher radial load capacity than equivalent ball bearings

- Dynamic load ratings ranging from 50kN to 1500kN

- Static load capacities up to 250% of dynamic ratings

Friction Optimization

- Coefficient of friction as low as 0.0011-0.0015

- Special roller crowning reduces edge stresses

- Advanced surface treatments minimize break-in wear

Speed Performance

- DN values (mm x rpm) exceeding 500,000

- Precision grades (P4, P2) available for ultra-high-speed operation

- Thermal stability up to 150°C continuous operation

3. Industrial Applications

Heavy Machinery

- Rolling mill stands

- Large gearbox applications

- Mining equipment bearings

Power Generation

- Turbine generator sets

- Hydroelectric turbine bearings

- Wind turbine main shafts

Transportation Systems

- Railroad traction motors

- Heavy truck wheel ends

- Marine propulsion systems

4. Maintenance Considerations

Lubrication Requirements

- Grease: NLGI 2 or 3

- Oil: ISO VG 68-220

- Re-lubrication intervals

Mounting Practices

- Proper interference fits

- Induction heating for installation

- Run-in procedures for new bearings

Failure Prevention

- Vibration monitoring thresholds

- Thermal imaging best practices

- Contamination control methods

5. Specialized Variants

Multi-Row Designs

- Double-row with axial load capacity

- Four-row for extreme radial loads

- Tandem arrangements for stiffness

Modified Geometries

- Logarithmic roller profiles

- Barrel-shaped rollers for misalignment

- Hybrid ceramic versions

Conclusion

Modern cylindrical roller bearings represent precision-engineered solutions for demanding industrial applications. Their optimized geometry and advanced materials deliver exceptional performance in load capacity, rotational accuracy, and service life. Proper selection and maintenance can significantly enhance machinery reliability and operational efficiency across multiple industries.