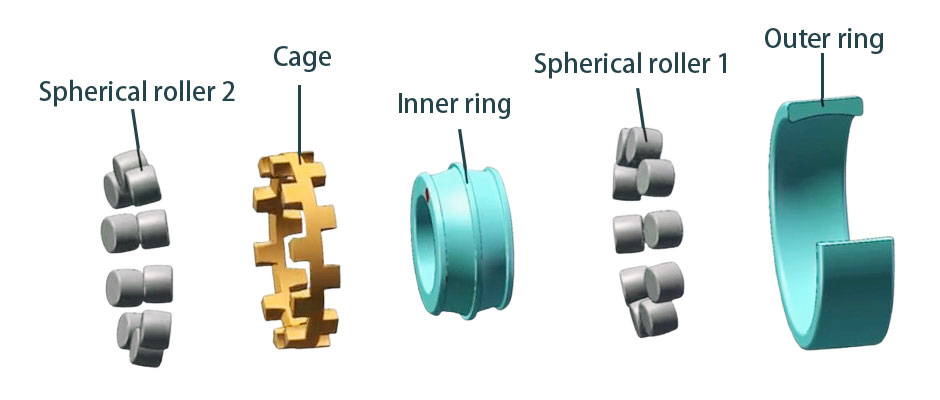

Spherical roller bearings, as crucial components in the field of machinery, feature ingenious structural designs. They are composed of an outer ring, an inner ring, two rows of spherical rollers, and a cage. The outer ring is equipped with a common spherical raceway. Notably, the center of curvature of this raceway precisely coincides with the center of the bearing. This sophisticated design endows spherical roller bearings with excellent self – aligning capabilities. They can operate stably and normally when the angular misalignment between the axes of the inner and outer rings does not exceed 3°.

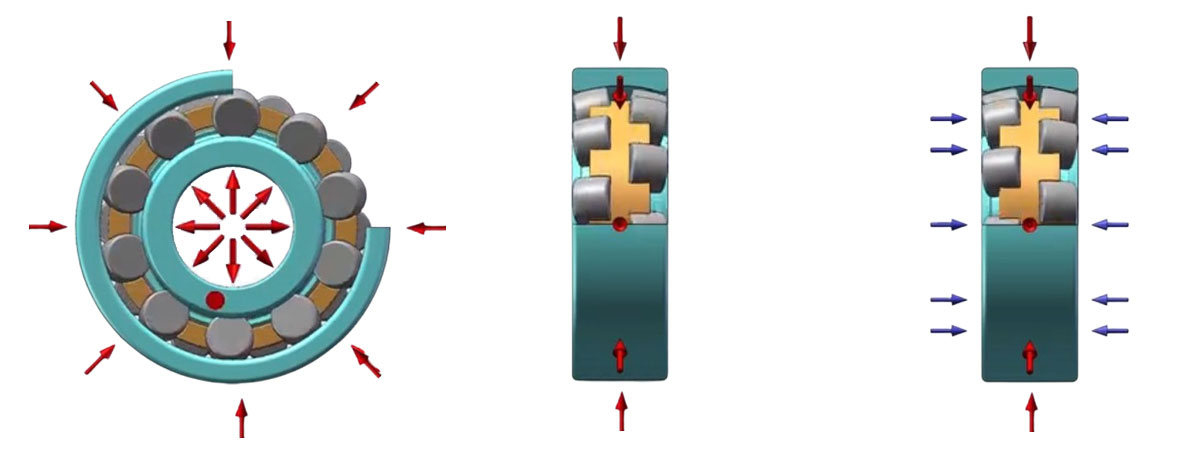

In terms of load – carrying performance, spherical roller bearings are primarily responsible for withstanding radial loads. Meanwhile, they also have a certain capacity to bear axial loads. However, it should be clearly noted that they are not suitable for withstanding pure axial loads. Compared with self – aligning ball bearings, spherical roller bearings have a superior load – carrying capacity and can better meet the requirements of heavy – duty operating conditions.