Definition

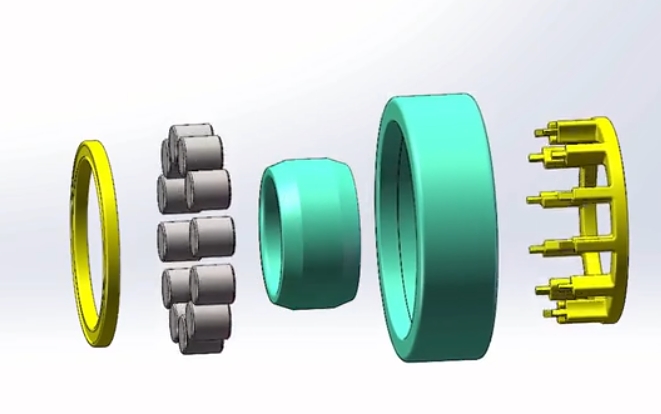

Cylindrical roller bearings are precision rolling-element bearings designed to carry high radial loads with low friction. They consist of:

- Cylindrical rollers guided by a cage

- Separable inner and outer rings

- Optional ribs for axial guidance

Types and Applications

| Type | Design Code | Typical Applications |

|---|---|---|

| Single row | N/NU/NJ/NF/NUP/NFP/NR/RNU | Gearboxes, electric motors, pumps, machine tool spindles |

| Double row | NN/NNU | Heavy machinery, rolling mills, large gear reducers |

| Multi row | NN30/NNU49 series | Rolling mill stands, extreme radial load situations |

| Full complement (Single-row) | NCF/NJG | Vibrating screens, construction equipment |

| Double-row Full-complement | NNC/NNCL/NNCF | Paper mill equipment, crane wheels |

| Four row | FC/FCD/FCDP series | Rolling mill work rolls, backup rolls |

Key Advantages

- 3-5x higher radial load capacity than ball bearings

- Low friction operation

- High-speed capability

- Long service life with proper lubrication

Selection Guide

- Load type: Pure radial → NU, Combined loads → NJ/NUP

- Precision: ABEC-1 (standard) to ABEC-5 (high-precision)

- Lubrication: Grease (for normal speeds) or oil (high-speed)

- Cage material: Steel (durability) or polymer (low friction)

Industry Applications

Energy

- Wind turbine gearboxes

- Hydroelectric generators

Transportation

- Railway axle boxes

- Marine propulsion systems

Heavy Industry

- Steel rolling mills

- Mining equipment

Technical Note

For custom bearing requirements or OEM solutions, consult with our Wafangdian-based engineering team to optimize bearing performance for your specific application.Standard materials: GCr15 bearing steel (ISO 9001), optional stainless steel or special coatings.