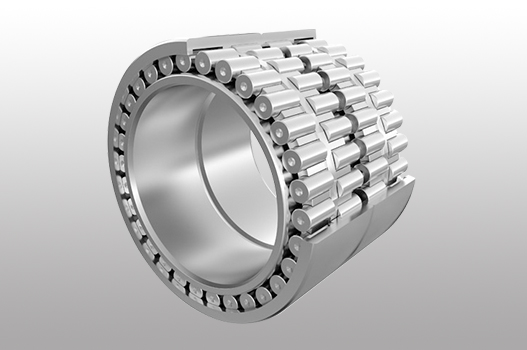

FCD106156570 Multi-Row Cylindrical Roller Bearing for Rolling Mills

Role in Rolling Mills

While rolling mills utilize various bearing types, multi-row cylindrical roller bearings are specifically engineered for applications requiring exceptional radial load capacity and rigid support in mill stands.

Typical Installations:

- Backup rolls in 4-high/6-high mills

- Plate mill support rolls

- Continuous casting machine rolls

- Non-drive end applications

Technical Advantages

Optimized Load Distribution

Four-row design shares loads across multiple roller paths for enhanced durability.

Precision Guidance

Maintains roll positioning within ±0.01mm tolerance for superior accuracy.

Thermal Stability

Special heat treatment resists deformation up to 150°C operating temperature.

Configuration Flexibility

Available in FC (solid) and FCD (split) designs for various applications.

Product Series Comparison

FCD Series (Split Inner Ring)

- FCD3045120 Easy maintenance

- FCD5678275 Cluster mills

Complementary Bearing Solutions

For complete rolling mill solutions, these bearings often work with:

Tapered Roller Bearings

- Work roll applications

- Drive-end installations

Thrust Bearings

- Axial load management

- Mill screw-down systems

Selection Guidelines

Load Analysis

Calculate dynamic equivalent load (P = Fr for pure radial)

Speed Considerations

DN value ≤ 300,000 mm/min

Lubrication

Prefer oil-air systems for high-speed applications

Technical Support Available

Our engineers can help select the optimal bearing configuration for your mill type and operating conditions.

Explore Our Multi-Row Cylindrical Roller BearingsRelated Bearing Types

Backing Bearings vs. Multi-Row Cylindrical Bearings

While multi-row cylindrical bearings are designed for backup rolls handling heavy radial loads, backing bearings are specialized for work roll support in cluster mill configurations, particularly in Sendzimir mills for precision strip rolling.