Deep Groove Ball Bearings: Essential Components for Machinery

Deep groove ball bearings are among the most widely used rolling bearings, renowned for their simple yet highly efficient design, playing a pivotal role in various machinery.

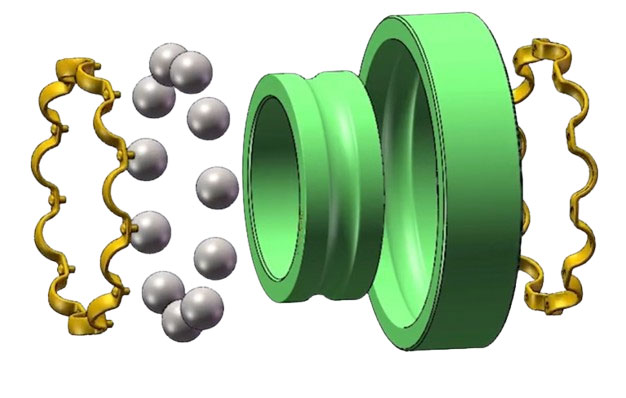

Four Key Components

Inner Ring

- Fitted tightly onto the shaft, it rotates in tandem with the shaft

- Features a smooth raceway for seamless rolling of elements

- Example: In electric motor rotor shafts, transmits power to other components

Outer Ring

- Usually secured within bearing housing or mechanical component holes

- Works with inner ring’s raceway to guide rolling elements

- Example: In automotive wheel hub bearings, supports the wheel’s weight

Rolling Elements (Steel Balls)

- Core elements enabling rolling friction

- Quantity and size vary based on bearing model and load requirements

- Provide stable support for equipment operation

Cage

- Separates steel balls to prevent collisions

- Guides ball movement

- Made from metal or non-metal materials depending on conditions

- Example: Plastic cages used in centrifuge bearings

Raceway Design

Both the inner and outer rings feature semi-circular deep grooves that perfectly match the steel balls. This design evenly distributes loads, allowing the bearing to handle both radial and a certain degree of axial forces, making it suitable for diverse working scenarios.

Sealing and Dust Protection

Dust Cover

- Stamped from steel plates

- Blocks dust in low-dust environments

- Example: Used in fan bearings for office equipment

Seals

- Contact Seals: Fit closely to prevent dust ingress and grease leakage (e.g., automotive engine water pump bearings)

- Non-contact Seals: Use special structure to seal without friction, suitable for high-speed applications in clean environments

Special Structures

Inner Ring with Snap Groove

- Features a groove on the outer ring

- Pairs with snap ring for simplified axial positioning

- Facilitates easier installation and maintenance

Bearing with Filling Slot

- Allows insertion of more steel balls

- Enhances load capacity

- Common in heavy-duty equipment

Double-row Structure

- Combination of two single-row bearings

- Provides higher load-bearing capacity

- Ensures stability in demanding applications