WJY (Wafangdian Jinyu) Bearing specializes in manufacturing medium/large bearings and precision mechanical components. We focus on R&D, production, and sales of high-quality bearings for global industries. Our key product, Backing Bearings, highlights our expertise in precision engineering and durability. With ISO 9001 certification, we ensure strict quality control and reliable solutions for mining, construction, and heavy machinery. Contact us for efficient bearing solutions.

Superior Material Selection & Durability

Our Backing Bearings are manufactured using high-grade carburized steel (G20Cr2Ni4A) with advanced heat treatment processes, ensuring exceptional wear resistance and extended service life. The deep carburized layer (≥2.0mm) provides a surface hardness of HRC60-64 and a tough core (HRC30-40), making them ideal for heavy-load and high-stress industrial environments.

P4-Grade Precision Engineering for Optimal Performance

We utilize state-of-the-art CNC machining and grinding technologies to achieve P4-grade precision (ISO P4/ABEC 9 standard):

- Dimensional tolerance controlled within ±2μm

- Roundness error ≤0.5μm

- Cylindricity error ≤1μm

- Surface roughness Ra ≤0.025μm

This precision enhances load distribution, reduces friction by up to 30%, and minimizes energy loss in machinery.

Application Fields

1. Metal Processing & Steel Industry

2. Mining & Quarrying

3. Construction & Heavy Engineering

4. Power Generation

5. Industrial Machinery

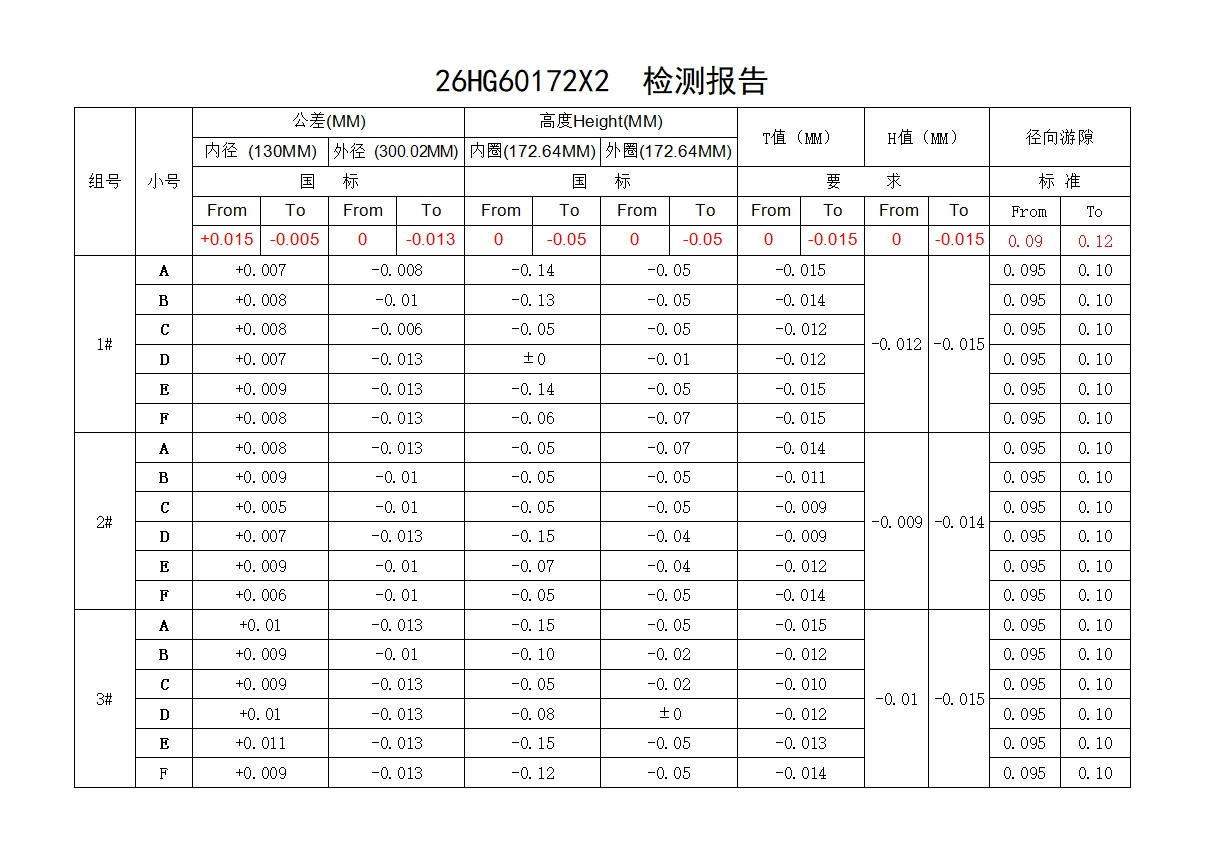

Rigorous Quality Control

Every Backing Bearing undergoes stringent inspection processes before leaving the factory, including dimensional checks, hardness testing, and dynamic performance evaluations, with inspection reports issued for traceability. Our ISO 9001 – certified quality management system ensures consistent reliability and compliance with international standards, providing our customers with the confidence that our products will perform flawlessly in their operations.