Lifting Mechanism Gearbox and Motor

The oil-immersed gear transmission mechanism adopts a three-stage speed reduction design, and the precision-machined gear set works in a leak-proof cast aluminum gearbox.

- Housing design promotes air cooling for optimal heat dissipation

- Easy-access maintenance points for quick servicing

- Dual-speed motor with 6:1 speed ratio (high:low)

- Low-headroom design maximizes workspace efficiency

Car Driving Drive System

The trolley adopts dual-wheel drive and is located on both sides of the main machine, which can provide uniform and efficient traction.

- Bilateral drive configuration ensures balanced movement

- Threaded gear transmission for smooth acceleration/deceleration

- Precision-engineered for minimal vibration during operation

Drum, Rope and End Fixed Lock

The coiling design of the hoisting mechanism wire rope can achieve the maximum lifting height while ensuring the low headroom size.

- Multi-layer spooling technology for compact rope storage

- Triple high-strength metal locks at rope termination

- 3-coil safety margin at minimum hook position

- Anti-corrosion treated wire rope for extended service life

Safety Systems

Upper and Lower Limiters

- Standard rotary vane circuit limiters

- Optional touch-type top limiter

Overload Protection

- Integrated load monitoring system

- Automatic cutoff at 110% rated capacity

- Mechanical and electronic dual protection

Pulley and Hook Assembly

The pulley is equipped with a rotatable hook as standard for maximum load maneuverability.

- 360° horizontal rotation capability

- 180° vertical articulation range

- Forged steel construction with safety latch

- Low-friction bearing system

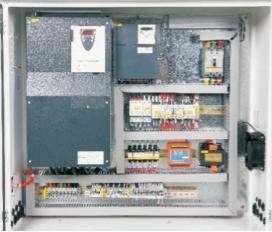

Control System

The enclosed control box of the hoisting mechanism mainframe and trolley control components has a protection level of IP54.

- Dust-proof and water-resistant enclosure

- Ergonomic pendant control option

- Fail-safe emergency stop circuit

- Modular design for easy component replacement